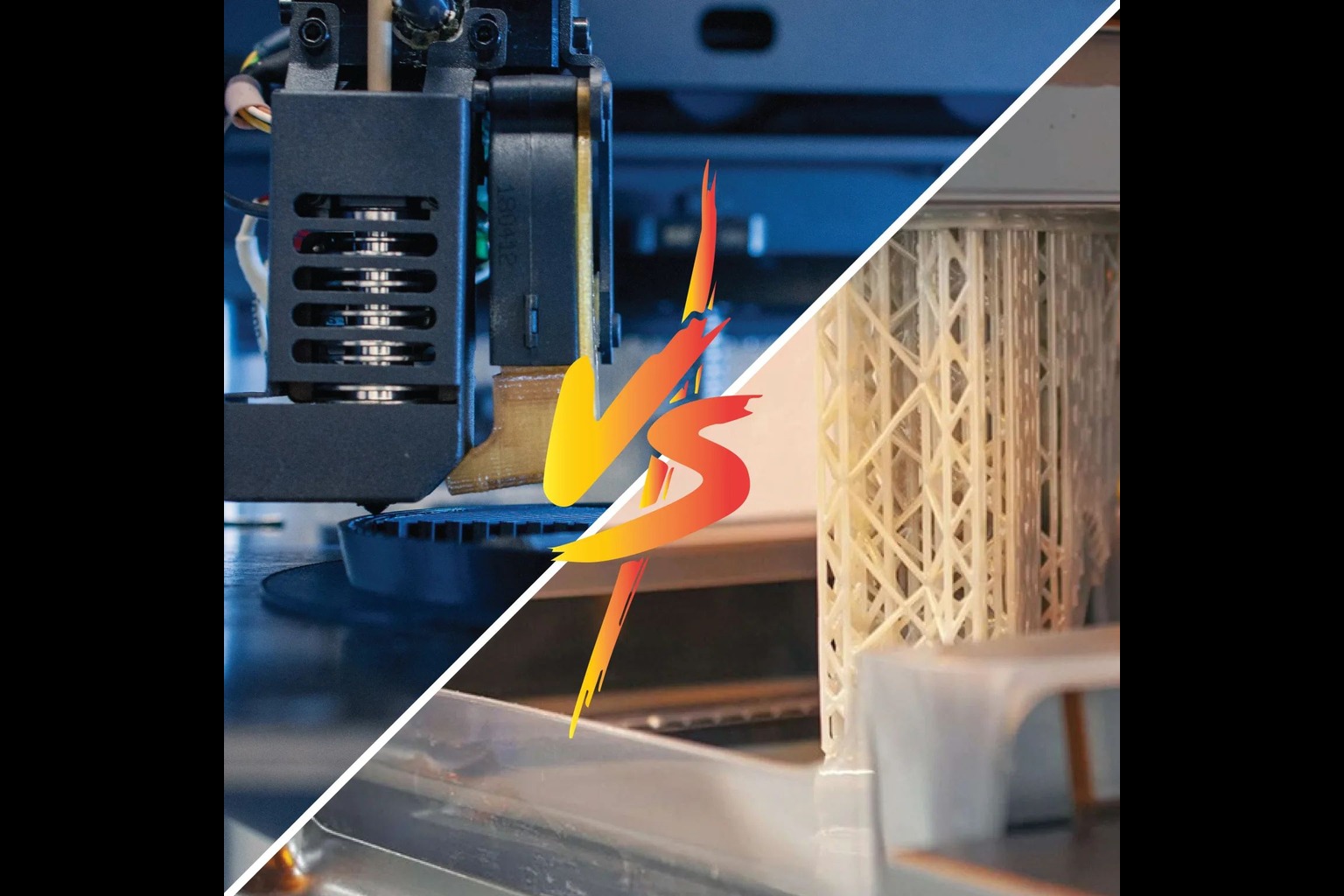

3D printing has revolutionized the way we design, prototype, and create. Among the most popular technologies are Resin (SLA/DLP) and Filament (FDM/FFF) printing. Each method has its strengths, weaknesses, and ideal applications. If you’re considering which one is right for your projects, here’s a detailed comparison of both.

⸻

1. Technology Basics

• Resin 3D Printing (SLA/DLP/MSLA):

Uses a photosensitive liquid resin that hardens when exposed to UV light. This process allows ultra-fine details and smooth surfaces.

• Filament 3D Printing (FDM/FFF):

Works by extruding heated thermoplastic filament layer by layer. It’s versatile, cost-effective, and widely accessible.

⸻

2. Print Quality & Detail

• Resin Printing:

• Exceptional surface smoothness.

• High precision and intricate details, making it perfect for figurines, jewelry, miniatures, and dental/medical models.

• Almost invisible layer lines.

• Filament Printing:

• Good structural strength.

• Best for larger, functional prototypes and engineering parts.

• Visible layer lines and less detail compared to resin.

⸻

3. Cost Considerations

• Resin Printing:

• Higher material cost (resins are more expensive than filaments).

• Requires additional equipment for post-processing (UV curing stations, isopropyl alcohol, etc.).

• Smaller build volume limits large-scale production.

• Filament Printing:

• Budget-friendly filament options (PLA, ABS, PETG, etc.).

• Lower maintenance costs.

• Larger build volumes make it cost-effective for big prints.

⸻

4. Ease of Use & Workflow

• Resin Printing:

• Requires post-processing (washing, curing, and handling of liquid resin).

• More preparation and clean-up involved.

• Safety measures needed due to resin’s chemical properties.

• Filament Printing:

• Easier to set up and operate.

• Minimal post-processing required.

• More beginner-friendly, though settings must be tuned for best results.

⸻

5. Creativity & Applications

• Resin Printing is ideal for:

• Miniatures and collectibles.

• Highly detailed prototypes.

• Artistic sculptures.

• Medical and dental models.

• Filament Printing is ideal for:

• Functional prototypes.

• Mechanical parts and enclosures.

• Larger decorative objects.

• Everyday practical items and hobby projects.

⸻

6. Pros and Cons at a Glance

Resin 3D Printing

✔ Smooth, detailed finish

✔ Perfect for intricate designs

✔ Professional-grade results

✘ Higher costs

✘ Requires post-processing

✘ Smaller build volume

Filament 3D Printing

✔ Affordable and accessible

✔ Larger build sizes possible

✔ Wide range of material choices

✘ Visible layer lines

✘ Less detail for complex parts

✘ Can be prone to warping with some materials

⸻

Conclusion

When it comes to resin vs. filament 3D printing, the choice depends on your priorities:

• If you value fine detail, smooth finishes, and high-resolution models, resin is the way to go.

• If you prioritize cost-efficiency, durability, and larger prints, filament is your best bet.

At Roar3D Creative Designs, we specialize in both resin and filament printing—delivering the best of both worlds for collectible figurines, custom gifts, décor, and functional prototypes. Whether you’re after creativity, precision, or practicality, we’ve got you covered.